Coining is a bending technique wherein the workpiece is stamped while placed between a die and the punch or press.

Pressing details into sheet metal.

Bending is one of the most common sheet metal fabrication operations.

This action causes the punch tip to penetrate the metal and results in accurate repeatable bends.

The metal used is 040 1 4 hard copper sheet.

Die stamping also referred to as pressing is one of the oldest forms of metal stamping.

Place the sheet metal in the correct position on the positive die and slide the negative on top.

It s like a little metal sandwich.

The force must exceed the material s yield strength to achieve a plastic deformation.

The indentations are 750 od 656 id and 156 deep.

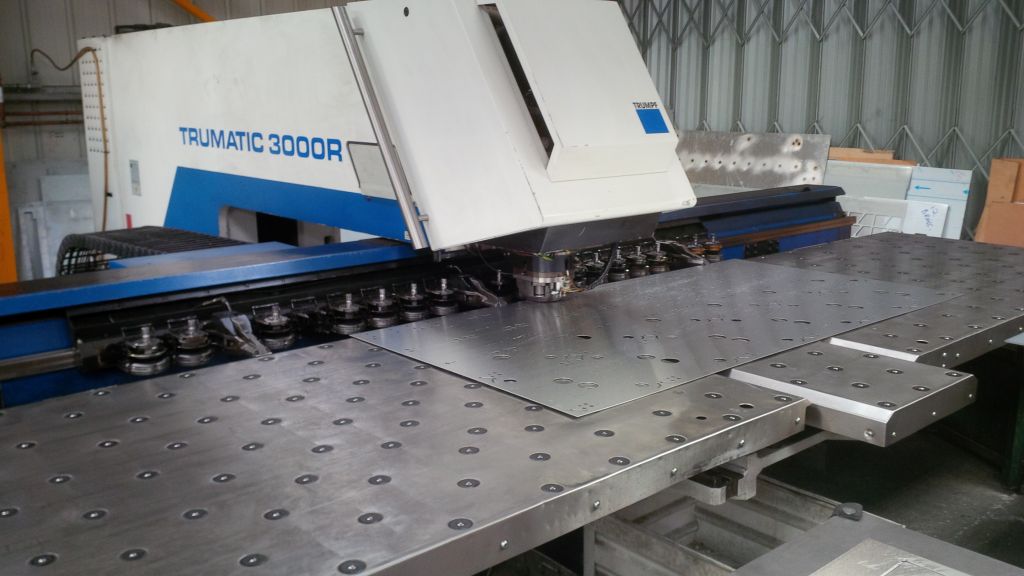

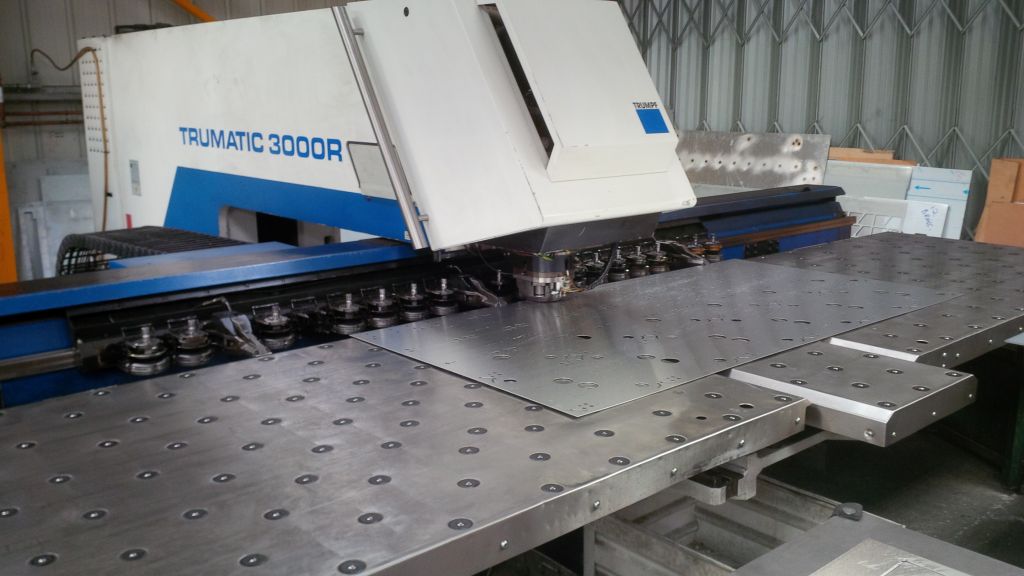

The main advantage of using this machine is they are the fastest and most efficient way to form any sheet metal into the finished product.

The process of shaping metals into semi finished or finished forms by passing between rollers is called rolling.

Stamping includes a variety of sheet metal forming manufacturing processes such as punching using a machine press or stamping press blanking embossing bending flanging and coining.

2 to form these bends.

The press is a metal forming machine tool used to shape or cut metal by applying mechanical force.

All other factors influencing sheet metal forming we should recall that a sheet metal forming operation can always be from the conceptual point of view.

Place this cylinder on top of the metal sandwich and place the entire assembly under the press.

The press is usually not yet known so that its characteristics are rather a factor of.

Rolling is the most widely used metal forming process.

Gives useful insights into the mechanics of a forming operation.

In both sheet metal is sunk or pressed into a die.

This is done through the application of force on a workpiece.

During this process a flat piece of sheet metal is placed into a press where a tool and die surface pushes the metal into a desired shape.

I made the jig in fig.

Stamping also known as pressing is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

I m trying to make some parts that require indentations in sheet metal see fig.

As you can see the sides of these dimples are close to perpindicular.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Hydraulic die forming is quicker and lends itself more to duplicating formed art or other production.

Find a long metal cylinder that will fit between the two stainless steel rods.

Die stamping and pressing.

The sheet metal takes the form of the design cut into the die.

Embossing is a process for creating either a raised or recessed design in sheet metal by pressing the raw blank against a die that contains the desired shape or by passing the material blank through a roller die.